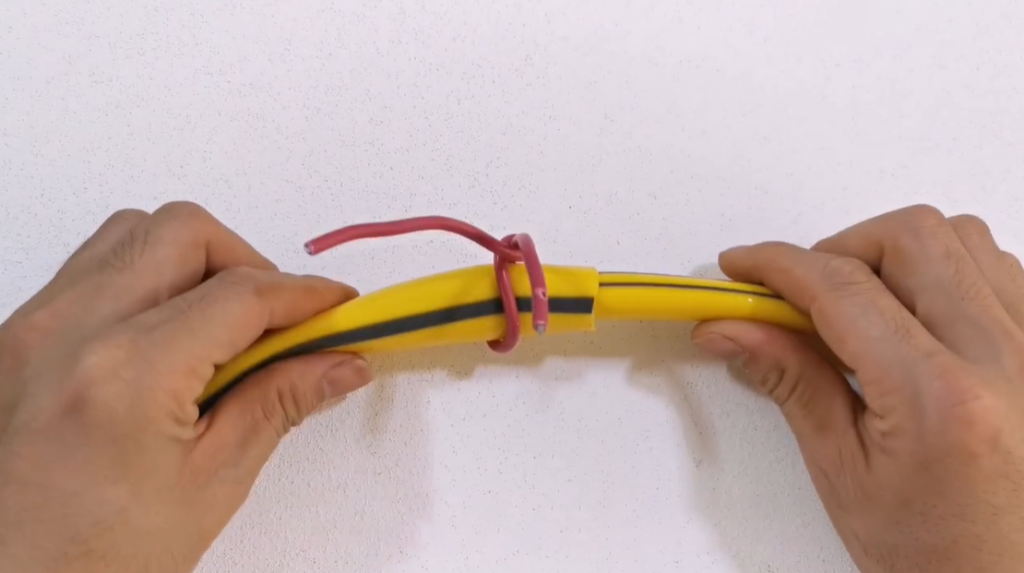

1. Direct plug-in connection method:

The direct plug-in connection method is particularly suitable for simple pipeline systems where ease of operation is a priority. To ensure a secure connection, it is crucial to insert the hose into the fitting with sufficient depth. Once the insertion is complete, it is advisable to use clips or straps to secure the connection further. This additional step helps to prevent any accidental detachment of the hose from the fitting, thereby maintaining the integrity of the system. The direct plug-in method is straightforward and does not require any special tools or skills, making it a popular choice for many applications.

2. Threaded connection method:

Threaded connections are commonly employed in plastic hose applications where threaded fittings are available. When using this method, it is essential to pay close attention to the direction of the threads. To ensure a smooth and secure connection, first carefully align the threads before rotation. This step is crucial because misalignment can twist or damage the threads, compromising the connection’s integrity. As you rotate the fitting, maintain this alignment to achieve a reliable seal. Thanks to its reliability and ease of disconnection and reconnection, this method remains widely adopted in various applications.

3. Utilizing specialized connectors for connection:

For scenarios where a more robust and reliable connection is required, utilizing specialized plastic connectors is highly recommended. These connectors often come with a built-in sealing gasket or O-ring, which significantly enhances the connection’s ability to prevent liquid leakage. Always follow the manufacturer’s instructions carefully when using these connectors. First, ensure the gasket or O-ring sits properly. Then, tighten the connection to exact specifications. This approach guarantees optimal performance.Using the appropriate tools during this process is crucial to achieve the necessary torque and ensure a secure fit. This method provides a high level of confidence in the connection’s ability to withstand pressure and prevent leaks.

4. Welding connection method:

In specific situations where superior sealing and strength are of utmost importance, such as in industrial applications, welding may be the preferred method for connecting plastic hoses. This method involves using professional plastic welding equipment and requires a certain level of skill to execute correctly. The goal is to create a weld that is free of bubbles, which could weaken the connection, and free of any virtual welds, which could lead to leaks. A thorough quality inspection after welding is essential to confirm that the weld is free of any defects and that the connection is indeed secure. Welding, when done correctly, can provide a level of strength and sealing that is unmatched by other connection methods, making it a valuable technique in certain applications.

In summary, the above paragraphs detail several common connection methods for plastic hoses. Each method boasts unique advantages, and what’s more, it fits different applications depending on the required security level and sealing performance.When selecting a connection method, it is essential to consider the specific needs of the application and choose accordingly to ensure a firm and leak-proof connection.